FIRST® Fabrication

Team 2337's Philanthropy, Focus, and Philosophy of FIRST® are very important, and although the robot is merely a vehicle, it is used to drive the Team's efforts. The EngiNERDs take every opportunity to teach ad learn new skills, and engineering a robot is an excellent instrument to achieve this.

Student Section LeadersEach component of the Robot is lead by a Student Section Leader, who is responsible for ensuring that their project is completed on time and in a safe manner that is congruent with the Team's game-specific strategy. Student Section Leaders are chosen each year by the Team's Head Mentors through a formal interview process.

|

Computer-Aided DesignCAD is always at the forefront of The EngiNERDs' fabrication. Before any parts are machined, they are designed in Autodesk Inventor, and the Student and Mentor in charge of machining receives detailed working drawings. These steps help the team save time during production and conserve raw material resources.

|

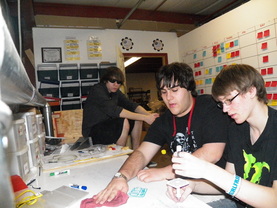

PrototypingPreceding many decisions for design and functionality, the EngiNERDs' Team members spend a significant amount of time developing working prototypes. These concept pieces might work as intended or may fail miserably, but each outcome is recorded to allow accurate data comparison.

|

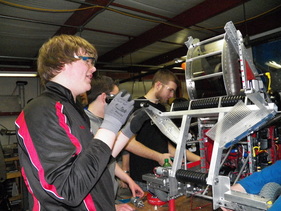

MachiningEach of the EngiNERDs' custom components are machined at the Team's facility, though a collaborative effort of all Team members. Students work directly beside or under the supervision of knowledgable Mentors to machine parts using one of the in-house Mills or Lathes. Aside from Commercial off-the-Shelf (COTS) items, nothing is outsourced for production.

|

Iterative Design ProcessOn Team 2337, there's no such thing as a final design. Through the process of iterative design, Team members frequently reevaluate the robot's components and look for areas in need of modification. The Team's commitment to continuous improvement allows objective assessment of subsystems, regardless of the effort required to complete necessary alterations.

|

TroubleshootingThroughout the six-week build period, and into competition season, the EngiNERDs use the techniques of debugging and troubleshooting to resolve many issues in the area of mechanical design, electrical wiring and programming. Often times, implementation of minor adjustments to a particular sub-system can help avoid major design changes, thus saving time and resources.

|

Emphasis on QualityTeam 2337 takes great pride in manufacturing a robot that is held to high standard of quality. From the types of materials that are selected to the tolerances that are held during machining, Students and Mentors believe that there is tremendous value in creating something the "right way" the first time.

|

OrganizationIn order to maximize Student and Mentor efficiency and knowledge, the EngiNERDs take pride in organizing materials and tools. Additionally, the Team primarily operates in a 10 foot by 10 foot "pit" area at their build facility, and arranges its tool boxes and workbenches in the same orientation at competitions.

|